Choose HeatShield® for Your Chimney Liner Repair

Have you looked your fireplace and chimney over recently? While it may appear fine on the outside, it’s important to schedule annual chimney inspections to identify problems that may be brewing beneath the surface – problems that could be putting your household at risk. Years of use can lead to damage, even with regular maintenance and proper care, so getting professional eyes on the job now and then is essential.

A common issue often uncovered during inspections is a deteriorated or damaged flue liner. Chimney flue liners can deteriorate over time due to extreme heat and exposure to water, and cracks and other damage are safety risks because they can lead to chimney fires or carbon monoxide leaks.

Some companies may suggest rebuilding the whole chimney or adding a new liner, but those options are expensive and time-consuming. Fortunately, there is another solution for homeowners in Southwest Missouri and Northwest Arkansas – HeatShield®. It’s a cost-effective chimney liner repair system that restores the integrity of your chimney flue liner without breaking the bank or taking up a bunch of your time in the process.

HeatShield® eliminates the hazards and draft problems caused by gaps, cracks, and spalling in masonry chimneys that are still structurally sound. If you are interested in chimney relining in the Greene County or Benton County area, reach out to Ozark Stove and Chimney today. We will inspect your chimney and tell you if HeatShield® is an option for you.

How Do I Know if My Chimney Needs a Liner Repair?

The only way to tell if your chimney needs to be relined is with a chimney inspection. To detect defects in your liner, internal camera equipment is needed, which means you’ll need to hire a company that provides level 2 chimney inspections – something we’d be happy to get done for you.

What kind of problems can lead to a relining? Ozark Stove and Chimney may recommend a relining if we find any of the following problems during an inspection:

- Cracked or eroded clay liners

- Cracked flue tiles

- Mortar between clay flue liners that is deteriorating

- Voids and cracks between flue tiles

- Spalled clay flue liners or tiles

What Causes a Chimney Flue To Fail?

Chimney flues can be damaged in several ways, like by creosote buildup or corrosive gases, but one of the biggest issues relates to water exposure.

Chimneys are quite vulnerable to water damage and natural wear and tear. The materials that make it up are water absorbent and, over time, rain and snow can seep into a chimney and it can lead to spalling brick and deteriorating mortar. Then, there’s the freeze/thaw cycle. In the Ozarks, cold weather kicks this process off, which impacts a chimney’s structural integrity.

What is this? The freeze/thaw cycle is when a chimney absorbs water during warmer days and then freezes when the temperature drops. The ice crystals expand, causing small cracks to form within the brick, and as this process continues during the winter season (and repeats year after year), the bricks and mortar begin to chip and crumble. If left untreated, the chimney can become unstable.

What Is HeatShield® for Chimneys?

For a long time, the only way to reline a damaged clay chimney liner was to install a metal stainless steel liner. This method required clay tiles to be removed, which is expensive and could cause more chimney damage. It also eats up a lot of your schedule. Installing a HeatShield® takes about half the time and allows you to keep the clay tiles intact, providing an affordable, effective, and – let’s be honest – easier alternative to replacing your chimney liner.

So… what is it exactly?

HeatShield® is a method of chimney repair developed in Europe over 20 years ago. HeatShield®’s Cerfractory® sealant is a hybrid ceramic/refractory coating that can withstand moisture, corrosive flue gases, and temperatures exceeding 2900 degrees Fahrenheit. It is rated a “Super-Duty” refractory mortar by the American Society for Testing and Materials (ASTM) C199 and surpasses the requirement by the National Fire Prevention Association (NFPA) and the International Residential Code (IRC) – which require only a “Medium-Duty” refractory mortar for use in fireplaces and chimneys.

Types of HeatShield® Relining

There are three methods used to repair chimney liners with HeatShield® – the Joint Repair System, the Resurfacing System, and the CeCure® Sleeve Relining System. If you decide that installing HeatShield® is the right choice for you, we will choose the method based on how much damage we find in your chimney.

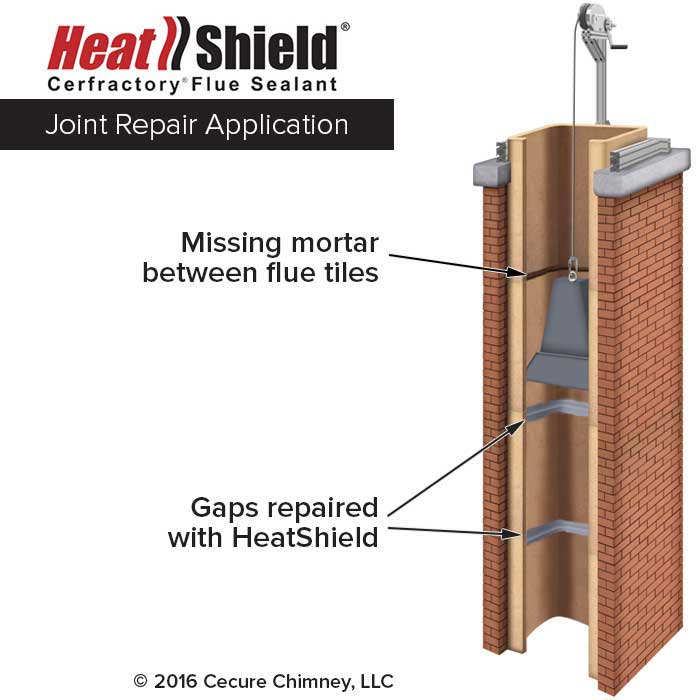

Joint Repair System

The Joint Repair System is used for chimneys that only require the repair of defective mortar joints, but the lining system is otherwise free of major damage. During this process, a foam applicator blade is custom-made to fit your chimney. The applicator is positioned below each gap or void, after which HeatShield®’s Cerfractory® Flue Sealant mixture is added. The applicator is then pulled up and each void in your flue is carefully filled – leaving your chimney with new sealed mortar joints.

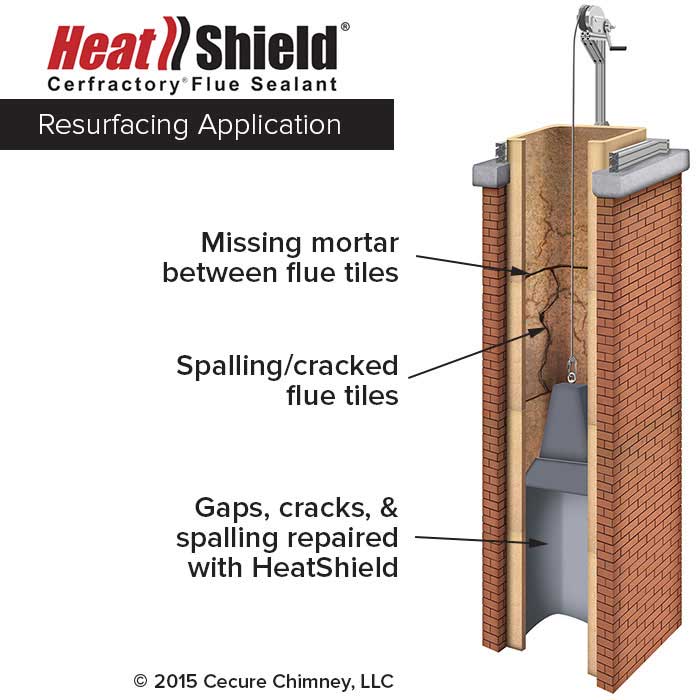

Resurfacing System

If the chimney has mortar joint defects along with other minor damage, like cracking and spalled flues, we will recommend the Resurfacing System method. For this process, a custom-made foam applicator plug is placed at the bottom of the flue and attached to a winch on top of the chimney. A “tie coat” material is applied to the flue walls as the plug is pulled upward by the winch. (The “tie coat” cleans any dust leftover in your flue and serves as a primer for the HeatShield® Cerfractory® Flue Sealant.)

After the “tie coat” has completely dried, the HeatShield® material is applied onto the flue at a thickness of about ¼”. This is called “slip casting” or “slip cast extrusion” and it leaves your chimney with a smooth liner. We use cameras to confirm that your chimneys mortar joints and flue tiles are completely sealed and smoke-tight.

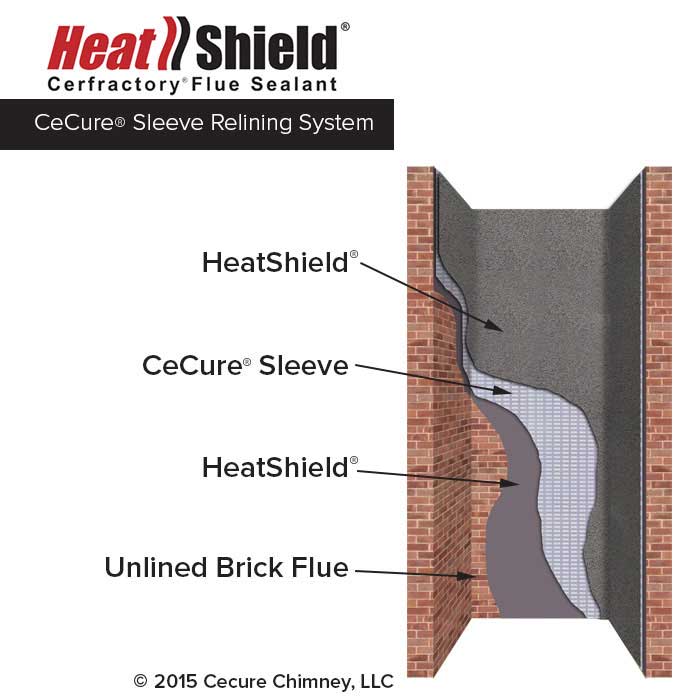

CeCure® Sleeve Relining System

HeatShield® can be used with the CeCure® Sleeve Relining System for unlined chimneys or chimneys with significant damage. The CeCure® Sleeve is a thin, ceramic insulation that has been reinforced with stainless steel fabric and is inserted between two coats of HeatShield® Cerfractory® Flue Sealant.

Similar to the Resurfacing System, an applicator plug is placed at the bottom of the flue and attached to a winch at the top of the chimney. A coating of HeatShield® Cerfractory® Flue Sealant is applied to the flue walls as the applicator plug is pulled upwards by the winch. Afterward, a custom-fitted CeCure® Sleeve is placed into the chimney and mechanically attached to the top of the chimney. The applicator plug is then pulled down through the CeCure® Sleeve to press it firmly into the first coating of HeatShield® Cerfractory® Flue Sealant. We finish it off with another coat of HeatShield® Cerfractory® Flue Sealant, and then we verify that the repair work has been completed correctly with an internal camera inspection.

Which is right for you? Schedule your appointment today to find out.

Why Should I Choose HeatShield® Over a Traditional Relining Method?

There are several methods for chimney liner repair and replacement but of those available, HeatShield® is one of the best options. Why?

- No Demo Work: There is no demolition with HeatShield®, so it’s less destructive and intrusive than other methods. The installation is also quicker and simpler than rebuilding your chimney or installing a metal liner, so you won’t have to worry about a lengthy construction project inconveniencing your life.

- Warranty Guarantee: HeatShield® is covered by a limited lifetime warranty.

- Improved Durability: HeatShield® is a long-lasting and durable liner solution that reinforces your chimney and extends its lifespan. Since it stands up against extreme heat, water absorption, and corrosive gases, your chimney will be more protected than ever before.

- Cost-Effective: You don’t have to wait to repair your chimney due to budget constraints. HeatShield® costs less than installing a metal chimney liner or rebuilding the chimney completely. It also takes about half the time of those other options.

- Environmentally Friendly: If you are an eco-conscious homeowner with a preference for green solutions, HeatShield® is a terrific option. It is created from recycled and naturally-occurring materials in nature.

- Better Efficiency: Your chimney cannot perform at its best if it’s damaged. Voids and gaps in the surface allow excess air into your chimney, slowing the updraft and trapping smoke and gases within your chimney. During the cold months, you may experience an increase in heating costs. Avoid it all with a new liner.

- Less Safety Risk: A cracked or damaged flue liner allows dangerous heated gases and toxins to escape into your home. According to the Chimney Safety Institute of America (CSIA), a damaged chimney flue can present serious risks to your home. It can also allow combustible creosote or soot to escape through these openings and build up outside the flue liner. When creosote catches fire in an affected area of your chimney, fire can no longer be contained within the flue and you may be at risk for a significant chimney fire. With HeatShield®, your family is better protected from potential hazards like chimney fires and carbon monoxide exposure.

It’s ultimately your decision as to which method is best, and the chimney technicians at Ozark Stove and Chimney will make recommendations that reflect the current state of your chimney. No matter which method you choose, we are fully prepared to proceed with any of the options – as long as it’s right (and safe) for you.

Is HeatShield® an Option for All Types of Chimneys?

HeatShield® is a good option for restoring or repairing most brick and masonry chimneys. It has been successfully tested on single, double, and triple-flue chimneys. It is compatible with all fuel types (wood, oil, gas, and coal) and meets Underwriters Laboratories (UL) standards. Unfortunately, HeatShield® cannot be used for metal and prefabricated flues repairs.

If you have questions about your chimney’s compatibility with HeatShield®, give us a call to schedule an inspection. Our technicians are certified by the CSIA and can recommend the correct relining method for your chimney type.

Before HeatShield

After HeatShield

Caring for Your Chimney After Installing HeatShield®

It is recommended that you do not use your chimney for 24 hours after HeatShield® is installed. Although we do use drying accelerators during installation, the bonding materials need time to cure completely. Think of your chimney as a freshly painted room – you may set up fans to help the paint dry, but you’d still wait awhile before running your hand along the walls.

In addition, you must keep up with regular chimney inspections and sweepings to ensure your flue stays in optimal condition. HeatShield® is one of the most durable options available to homeowners, but the most effective way to prevent future chimney damage is to keep up with regular maintenance.

How Much Does HeatShield® Cost?

HeatShield® is very cost-effective when compared to other relining options on the market. Since it can be completed more quickly and does not require demolition like other methods, you won’t be paying nearly as much for labor and materials.

Our chimney professionals at Ozark Stove and Chimney will guide you through which of the methods – Joint Repair System, the Resurfacing System, or the CeCure® Sleeve Relining System – is best for your chimney. After which, we can give you an accurate cost estimate.

Can I Install HeatShield® Myself?

You can only install HeatShield® if you are an approved HeatShield® Installer. The HeatShield® Cerfractory® Flue Sealant and CeCure Sleeve Liner System are only available through a network of factory-trained, independent installers.

How does someone become a HeatShield® Installer? By undergoing rigorous training and education through SaverSystems. Acceptance to SaverSystems is limited and based on industry experience, education, certifications, peer references, and course availability.

After a technician has completed the training program, they can purchase HeatShield® products as long as they continue meeting the following requirements:

- Certifications from one or more nationally recognized education and certification organizations.

- Membership in the National Chimney Sweep Guild (NCSG) and/or Hearth, Patio & Barbecue Association (HPBA) with strict adherence to the published “Code of Ethics.”

- Your company must currently offer Level II inspections per the National Fire Protection Association (NFPA) 211.

- Must have completed the HeatShield Installer factory training course.

Fortunately for those in the Greene County, MO and Benton County, AR area, our techs check all the boxes and are able to get the job done. Reach out now.

Schedule With Us Now

The team at Ozark Stove and Chimney is here to help you and get you scheduled for an inspection. We serve residents in Green County, Christian County, Stone County, Dallas County, Benton County, Marion County, and more. If you are not sure if we provide services in your area, get in touch with us and one of our customer service representatives will be happy to clarify.

Once booked, one of our CSIA-certified technicians will thoroughly check your chimney and flue for signs of damage and will recommend a relining solution based on their findings. If you are ready to schedule or have questions, reach out to us at 417-201-6585 or schedule an appointment online.

Find out about all of our chimney relining options, as well as the other chimney services, like dryer vent cleaning and chimney sweeping, that we offer all our customers.